Our Customer Stories

We're proud of what we build, but we are even prouder of the stories our customers share.

Our Customer Stories

We're proud of what we build, but we are even prouder of the stories our customers share.

Watch Their Stories of Transformation

Mark Johnson

(24-year homeowner)

"This has been a game changer for Debbie and I to be able to sit out on our porch, close these screens, and still look out in the river. I'm kicking myself that I didn't do it sooner."

Cary Paige

(Aquagrille Ponte Vedra Beach)

"The guests don't believe me when I say, 'Let's go outside.' When they're walking into the restaurant and it's cold, I say, 'Trust me, if you're not comfortable, I will buy you dinner.' That's where they want to sit now."

Tiffany Thomas

(Spain & Cooper Custom Homes)

"Our client was really looking to increase the flow from inside the home to outside... It allows you to really have more entertainment space, a cozy environment."

Freddie Wehbe

(Spurrier's Gridiron Grille)

"When those 65 seats are needed, we can use them now... It really is such a popular restaurant since the moment it opened."

Jim Michelli

(Sanford Verticals)

"These are, in my opinion, the highest quality outdoor screens you can buy. And they hold up to that in use day-to-day."

Melanie Frasier

(Titan Outdoor Solutions)

"They have screens from a competitor and those aren't working out for them. They're having a lot of troubles, a lot of issues with them."

Watch Their Stories of Transformation

Mark Johnson

(24-year homeowner)

"This has been a game changer for Debbie and I to be able to sit out on our porch, close these screens, and still look out in the river. I'm kicking myself that I didn't do it sooner."

Cary Paige

(Aquagrille Ponte Vedra Beach)

"The guests don't believe me when I say, 'Let's go outside.' When they're walking into the restaurant and it's cold, I say, 'Trust me, if you're not comfortable, I will buy you dinner.' That's where they want to sit now."

Tiffany Thomas

(Spain & Cooper Custom Homes)

"Our client was really looking to increase the flow from inside the home to outside... It allows you to really have more entertainment space, a cozy environment."

Freddie Wehbe

(Spurrier's Gridiron Grille)

"When those 65 seats are needed, we can use them now... It really is such a popular restaurant since the moment it opened."

Jim Michelli

(Sanford Verticals)

"These are, in my opinion, the highest quality outdoor screens you can buy. And they hold up to that in use day-to-day."

Melanie Frasier

(Titan Outdoor Solutions)

"They have screens from a competitor and those aren't working out for them. They're having a lot of troubles, a lot of issues with them."

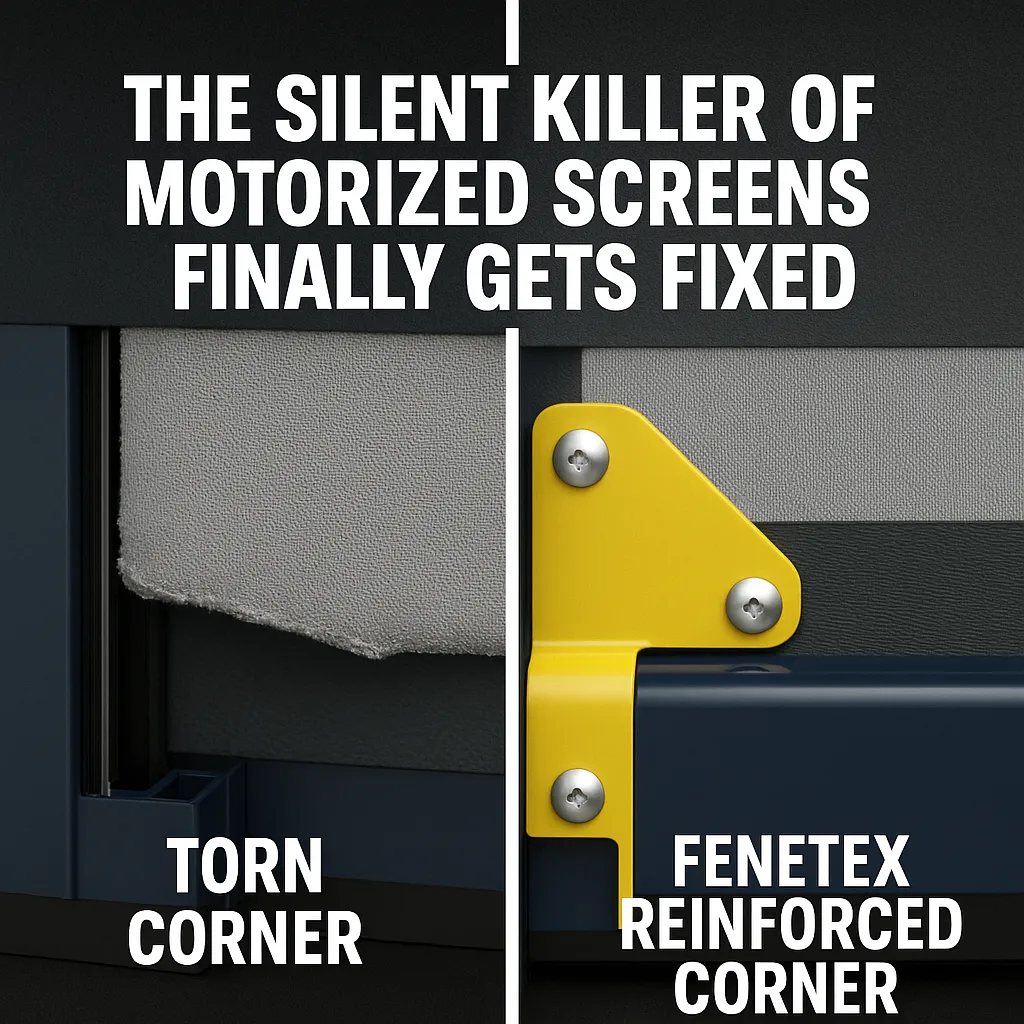

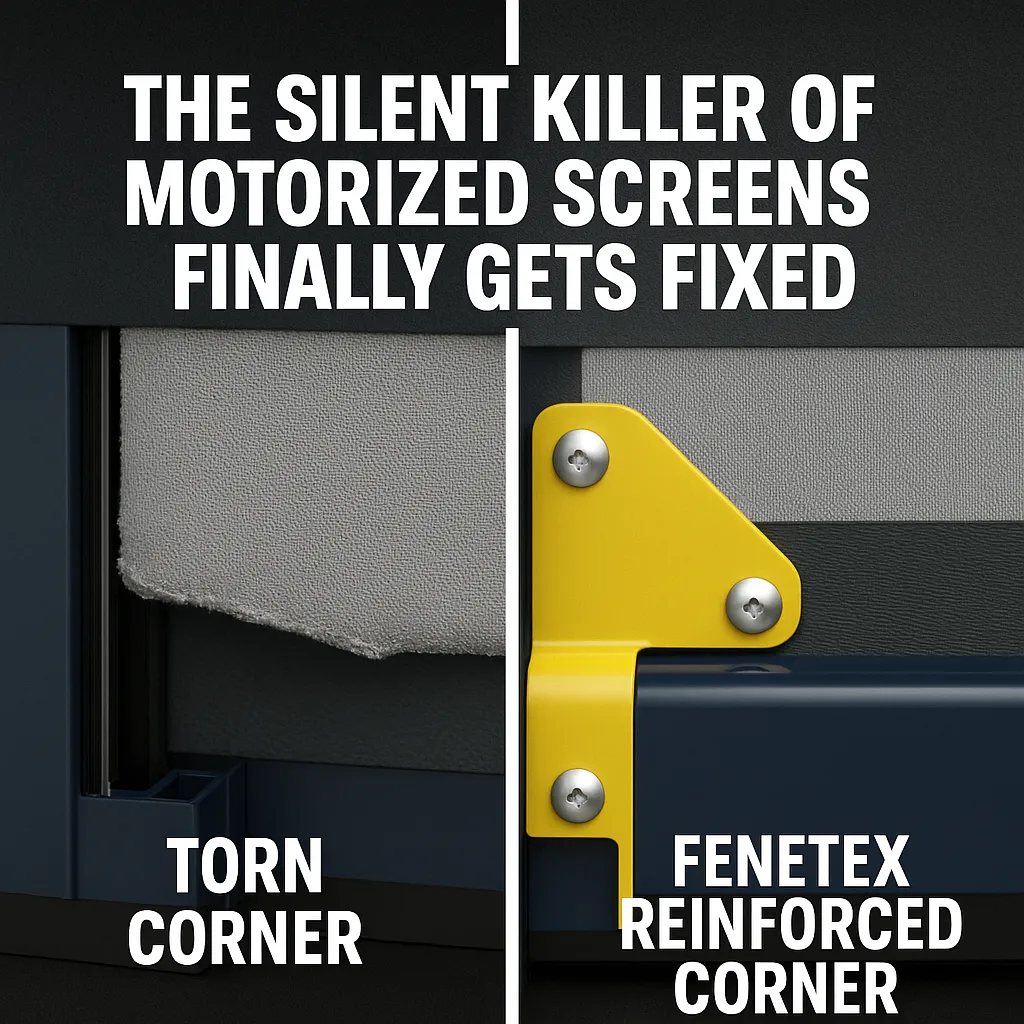

The Silent Killer of Motorized Screens Finally Gets Fixed

Your motorized screen will fail at the corner. Not might fail. Will fail.

It's physics meeting profit margins, and physics always wins. Unless, of course, someone decides to rewrite the rules entirely. That's exactly what happened in a Jacksonville workshop where engineers got tired of watching the same failure happen over and over—screens tearing where the weight bar meets the fabric, right at that vulnerable corner junction where stress concentrates like rush hour traffic through a single toll booth.

The Thousand-Dollar Tear Nobody Talks About

Picture this: You're hosting a dinner party on your screened patio. The sun sets. Someone reaches for the remote to lower the screens, and there it is—that dreaded ripping sound. The corner has given way. Again. Your guests pretend not to notice while you mentally calculate another $1,200 replacement cost, wondering why a product marketed as "premium" keeps failing at the same exact spot.

Here's what the industry doesn't advertise: corners bear the brunt of every operation cycle. Every raise, every lower, every gust of wind channels force through these junction points. The screen material pulls one way, the weight bar pulls another, and right there at the corner? That's where materials surrender to physics.

Traditional motorized screens treat corners like an afterthought. They stitch, they glue, they hope. Meanwhile, homeowners from Miami to Minneapolis discover the same truth: their "lifetime" investment has a countdown timer, and it's measured in corner stress cycles.

Why Corners Crack Under Pressure

The engineering challenge reads like a riddle wrapped in a warranty exclusion. How do you connect flexible screen material to a rigid aluminum weight bar while accommodating constant movement, temperature swings from -20°F to 120°F, hurricane-force winds, and the occasional wayward pool float?

Most manufacturers punt. They use the same connection methods from 1987, back when motorized screens were a novelty and not a necessity. These legacy corners rely on friction, faith, and fine print. The screen fabric gets pinched, sewn, or glued to the weight bar, creating a stress concentration point that would make any engineer wince.

Think about it. Every time your screen deploys, the corner experiences what engineers call "cyclic loading"—repeated stress that accumulates like compound interest, except instead of growing wealth, it's growing weakness. Add wind load, and that corner becomes a ticking time bomb of fabric fatigue.

The results are predictable. Screens start popping out of their tracks. Motors strain against uneven loads, overheating until their thermal protection kicks in, leaving you with a half-lowered screen and a house full of mosquitoes. Service technicians know the drill—they've seen it hundreds of times. The corner failed, the screen's compromised, and the only solution involves four figures and a two-week wait for replacement parts.

The Nylon Revolution Nobody Saw Coming

Enter Fenetex's engineering team with a different question: What if we stopped fighting physics and started working with it?

The answer came from an unexpected place—the sailing industry. Yacht sails endure similar stress patterns at connection points, facing wind loads that would destroy ordinary fabrics. The solution? Toughened nylon guides that flex without failing, strong enough to handle force yet supple enough to move naturally.

Fenetex's reinforced corner system doesn't just connect the screen to the weight bar; it creates a stress-distribution network. Imagine the difference between hanging a heavy picture with a single nail versus using a properly anchored mounting system. One creates a failure point; the other creates stability.

This toughened nylon guide wraps the critical corner junction, spreading load across a larger area while maintaining flexibility. It's overengineered in the best way—built to handle forces that screens will never actually face, which means handling daily operation becomes effortless.

The magic lives in the molecular structure. Standard connections create rigid stress points where materials can't move naturally. The nylon guide allows controlled flex, like shock absorbers for your screen corners. Force hits, disperses, dissipates. The screen material stays intact, the weight bar maintains alignment, and that catastrophic corner tear? It simply doesn't happen.

Real-World Proof in Hurricane Alley

Jacksonville isn't just Fenetex's hometown; it's their testing ground. Florida weather throws everything at outdoor products—blazing sun, torrential rain, salt air, and the occasional hurricane that redefines "wind load." If a screen corner can survive here, it can survive anywhere.

The numbers tell the story. Traditional corners show stress fractures within 18 months of installation in high-wind areas. Fenetex's reinforced corners? They're pulling five-year performance reports with zero corner-related failures. Zero. In an industry where 30% failure rates are considered acceptable, that's not an improvement—it's a revolution.

One installer in Naples reported something remarkable: "We used to budget three corner-failure service calls per month. Since switching to Fenetex's reinforced system two years ago, we've had exactly one, and that was from hurricane debris impact, not corner failure."

The real test isn't about certifications—it's about impact resistance and sustained performance. While competitors chase paperwork for High Velocity Hurricane Zones that don't even govern most installations, Fenetex focuses on actual engineering. Their reinforced corners exceed impact testing standards by margins that make failures essentially impossible. No certification sticker needed when the physics speak for themselves.

The Installation Secret That Changes Everything

Here's where craftsmanship meets engineering. A reinforced corner only works if it's installed correctly, and most installers treat corners like every other part of the screen. Wrong approach.

Proper corner installation requires understanding load paths—how force travels through the system. Too much initial tension, and you pre-stress the corner. Too little, and the screen sags, creating different stress patterns. The sweet spot requires experience, precision, and something most installers lack: patience.

Fenetex dealers undergo specific corner-installation training. They learn to read the screen's tension like a guitar string—tight enough to perform, not so tight it snaps. They understand that corners need special attention during setup, that rush jobs create callback nightmares, and that doing it right the first time saves everyone money.

The difference shows immediately. Properly installed reinforced corners allow screens to operate silently, smoothly, and consistently. No binding, no struggling motors, no mysterious noises that herald impending failure. Just reliable operation, day after day, season after season.

What This Means for Your Investment

Let's talk money, because corner failure isn't just inconvenient—it's expensive.

Average corner-failure repair: $600-$1,200, not including the service call. Frequency: every 2-3 years with traditional systems. Do the math over a decade, and you're looking at $3,000-$6,000 in corner-related repairs alone. That's assuming prices don't increase and you don't factor in the aggravation of scheduled repairs, unusable outdoor spaces, and explaining to guests why your "premium" screens look raggedy.

Fenetex's reinforced corners flip this equation. The additional engineering adds minimal upfront cost—we're talking maybe 3-5% of total system price. But it eliminates the corner-failure cycle entirely. No repairs, no replacements, no service calls for corner issues. Your screens operate as intended for their actual lifetime, not the warranty-limited version competitors offer.

Consider the intangibles too. Peace of mind during storm season, knowing your screens won't fail when you need them most. Confidence when lowering screens in front of guests. The simple pleasure of pushing a button and having things work correctly, every time, without drama or doubt.

The Quality Question Nobody Asks

Why doesn't everyone reinforce corners if it's so obviously beneficial?

Simple: it's expensive to engineer, costly to manufacture, and requires retraining entire installation networks. Most motorized screen companies are now owned by private equity firms focused on quarterly returns, not decade-long performance. They've calculated that warranty exclusions and replacement sales are more profitable than solving the problem.

Fenetex remains family-owned, engineering-driven, and stubbornly committed to building screens that last. They'd rather invest in toughened nylon guides than lawyers writing warranty exclusions. It's old-school thinking in the best way—build it right, stand behind it, and let performance speak louder than marketing.

This philosophy extends beyond corners. Every component gets the same scrutiny, the same over-engineering, the same refusal to compromise. It's why Fenetex screens cost more initially and less over time. The math only works if you're planning to keep your screens for years, not seasons.

Your Next Move Matters

Standing in front of a failed motorized screen, homeowners face three choices.

Replace with the same system and expect different results—Einstein had thoughts about this approach. Upgrade to a supposedly "better" brand that likely uses identical corner technology. Or recognize that Fenetex solved the corner problem and invest in engineering that actually works.

The choice seems obvious, but habits die hard. Dealers push what they know, what's easy, what generates repeat service revenue. They'll talk about warranties while knowing corners are excluded. They'll promise better results while installing the same failure-prone technology.

Ask one question: "How are your corners reinforced?" Watch them scramble. Listen to the vague responses about "strong materials" and "quality construction." Then ask about toughened nylon guides, stress distribution, and corner-specific engineering. The silence will be educational.

The Engineering Advantage You Deserve

Your outdoor space deserves better than products designed to fail. Your investment deserves protection beyond legal disclaimers. Your family deserves screens that work when needed, without drama or recurring repair bills.

Fenetex's reinforced corners represent more than clever engineering; they're a philosophy made physical. A belief that products should last, that corners matter, that solving problems beats managing failures. It's the difference between companies that sell screens and engineers who solve problems.

The corner where your screen meets the weight bar will face thousands of stress cycles, weather extremes, and unexpected impacts. You can choose corners designed in 1987 or corners engineered for reality. One will fail. One won't.

The choice, like the corner stress, is entirely yours to manage.

The Silent Killer of Motorized Screens Finally Gets Fixed

Your motorized screen will fail at the corner. Not might fail. Will fail.

It's physics meeting profit margins, and physics always wins. Unless, of course, someone decides to rewrite the rules entirely. That's exactly what happened in a Jacksonville workshop where engineers got tired of watching the same failure happen over and over—screens tearing where the weight bar meets the fabric, right at that vulnerable corner junction where stress concentrates like rush hour traffic through a single toll booth.

The Thousand-Dollar Tear Nobody Talks About

Picture this: You're hosting a dinner party on your screened patio. The sun sets. Someone reaches for the remote to lower the screens, and there it is—that dreaded ripping sound. The corner has given way. Again. Your guests pretend not to notice while you mentally calculate another $1,200 replacement cost, wondering why a product marketed as "premium" keeps failing at the same exact spot.

Here's what the industry doesn't advertise: corners bear the brunt of every operation cycle. Every raise, every lower, every gust of wind channels force through these junction points. The screen material pulls one way, the weight bar pulls another, and right there at the corner? That's where materials surrender to physics.

Traditional motorized screens treat corners like an afterthought. They stitch, they glue, they hope. Meanwhile, homeowners from Miami to Minneapolis discover the same truth: their "lifetime" investment has a countdown timer, and it's measured in corner stress cycles.

Why Corners Crack Under Pressure

The engineering challenge reads like a riddle wrapped in a warranty exclusion. How do you connect flexible screen material to a rigid aluminum weight bar while accommodating constant movement, temperature swings from -20°F to 120°F, hurricane-force winds, and the occasional wayward pool float?

Most manufacturers punt. They use the same connection methods from 1987, back when motorized screens were a novelty and not a necessity. These legacy corners rely on friction, faith, and fine print. The screen fabric gets pinched, sewn, or glued to the weight bar, creating a stress concentration point that would make any engineer wince.

Think about it. Every time your screen deploys, the corner experiences what engineers call "cyclic loading"—repeated stress that accumulates like compound interest, except instead of growing wealth, it's growing weakness. Add wind load, and that corner becomes a ticking time bomb of fabric fatigue.

The results are predictable. Screens start popping out of their tracks. Motors strain against uneven loads, overheating until their thermal protection kicks in, leaving you with a half-lowered screen and a house full of mosquitoes. Service technicians know the drill—they've seen it hundreds of times. The corner failed, the screen's compromised, and the only solution involves four figures and a two-week wait for replacement parts.

The Nylon Revolution Nobody Saw Coming

Enter Fenetex's engineering team with a different question: What if we stopped fighting physics and started working with it?

The answer came from an unexpected place—the sailing industry. Yacht sails endure similar stress patterns at connection points, facing wind loads that would destroy ordinary fabrics. The solution? Toughened nylon guides that flex without failing, strong enough to handle force yet supple enough to move naturally.

Fenetex's reinforced corner system doesn't just connect the screen to the weight bar; it creates a stress-distribution network. Imagine the difference between hanging a heavy picture with a single nail versus using a properly anchored mounting system. One creates a failure point; the other creates stability.

This toughened nylon guide wraps the critical corner junction, spreading load across a larger area while maintaining flexibility. It's overengineered in the best way—built to handle forces that screens will never actually face, which means handling daily operation becomes effortless.

The magic lives in the molecular structure. Standard connections create rigid stress points where materials can't move naturally. The nylon guide allows controlled flex, like shock absorbers for your screen corners. Force hits, disperses, dissipates. The screen material stays intact, the weight bar maintains alignment, and that catastrophic corner tear? It simply doesn't happen.

Real-World Proof in Hurricane Alley

Jacksonville isn't just Fenetex's hometown; it's their testing ground. Florida weather throws everything at outdoor products—blazing sun, torrential rain, salt air, and the occasional hurricane that redefines "wind load." If a screen corner can survive here, it can survive anywhere.

The numbers tell the story. Traditional corners show stress fractures within 18 months of installation in high-wind areas. Fenetex's reinforced corners? They're pulling five-year performance reports with zero corner-related failures. Zero. In an industry where 30% failure rates are considered acceptable, that's not an improvement—it's a revolution.

One installer in Naples reported something remarkable: "We used to budget three corner-failure service calls per month. Since switching to Fenetex's reinforced system two years ago, we've had exactly one, and that was from hurricane debris impact, not corner failure."

The real test isn't about certifications—it's about impact resistance and sustained performance. While competitors chase paperwork for High Velocity Hurricane Zones that don't even govern most installations, Fenetex focuses on actual engineering. Their reinforced corners exceed impact testing standards by margins that make failures essentially impossible. No certification sticker needed when the physics speak for themselves.

The Installation Secret That Changes Everything

Here's where craftsmanship meets engineering. A reinforced corner only works if it's installed correctly, and most installers treat corners like every other part of the screen. Wrong approach.

Proper corner installation requires understanding load paths—how force travels through the system. Too much initial tension, and you pre-stress the corner. Too little, and the screen sags, creating different stress patterns. The sweet spot requires experience, precision, and something most installers lack: patience.

Fenetex dealers undergo specific corner-installation training. They learn to read the screen's tension like a guitar string—tight enough to perform, not so tight it snaps. They understand that corners need special attention during setup, that rush jobs create callback nightmares, and that doing it right the first time saves everyone money.

The difference shows immediately. Properly installed reinforced corners allow screens to operate silently, smoothly, and consistently. No binding, no struggling motors, no mysterious noises that herald impending failure. Just reliable operation, day after day, season after season.

What This Means for Your Investment

Let's talk money, because corner failure isn't just inconvenient—it's expensive.

Average corner-failure repair: $600-$1,200, not including the service call. Frequency: every 2-3 years with traditional systems. Do the math over a decade, and you're looking at $3,000-$6,000 in corner-related repairs alone. That's assuming prices don't increase and you don't factor in the aggravation of scheduled repairs, unusable outdoor spaces, and explaining to guests why your "premium" screens look raggedy.

Fenetex's reinforced corners flip this equation. The additional engineering adds minimal upfront cost—we're talking maybe 3-5% of total system price. But it eliminates the corner-failure cycle entirely. No repairs, no replacements, no service calls for corner issues. Your screens operate as intended for their actual lifetime, not the warranty-limited version competitors offer.

Consider the intangibles too. Peace of mind during storm season, knowing your screens won't fail when you need them most. Confidence when lowering screens in front of guests. The simple pleasure of pushing a button and having things work correctly, every time, without drama or doubt.

The Quality Question Nobody Asks

Why doesn't everyone reinforce corners if it's so obviously beneficial?

Simple: it's expensive to engineer, costly to manufacture, and requires retraining entire installation networks. Most motorized screen companies are now owned by private equity firms focused on quarterly returns, not decade-long performance. They've calculated that warranty exclusions and replacement sales are more profitable than solving the problem.

Fenetex remains family-owned, engineering-driven, and stubbornly committed to building screens that last. They'd rather invest in toughened nylon guides than lawyers writing warranty exclusions. It's old-school thinking in the best way—build it right, stand behind it, and let performance speak louder than marketing.

This philosophy extends beyond corners. Every component gets the same scrutiny, the same over-engineering, the same refusal to compromise. It's why Fenetex screens cost more initially and less over time. The math only works if you're planning to keep your screens for years, not seasons.

Your Next Move Matters

Standing in front of a failed motorized screen, homeowners face three choices.

Replace with the same system and expect different results—Einstein had thoughts about this approach. Upgrade to a supposedly "better" brand that likely uses identical corner technology. Or recognize that Fenetex solved the corner problem and invest in engineering that actually works.

The choice seems obvious, but habits die hard. Dealers push what they know, what's easy, what generates repeat service revenue. They'll talk about warranties while knowing corners are excluded. They'll promise better results while installing the same failure-prone technology.

Ask one question: "How are your corners reinforced?" Watch them scramble. Listen to the vague responses about "strong materials" and "quality construction." Then ask about toughened nylon guides, stress distribution, and corner-specific engineering. The silence will be educational.

The Engineering Advantage You Deserve

Your outdoor space deserves better than products designed to fail. Your investment deserves protection beyond legal disclaimers. Your family deserves screens that work when needed, without drama or recurring repair bills.

Fenetex's reinforced corners represent more than clever engineering; they're a philosophy made physical. A belief that products should last, that corners matter, that solving problems beats managing failures. It's the difference between companies that sell screens and engineers who solve problems.

The corner where your screen meets the weight bar will face thousands of stress cycles, weather extremes, and unexpected impacts. You can choose corners designed in 1987 or corners engineered for reality. One will fail. One won't.

The choice, like the corner stress, is entirely yours to manage.

Go-Fenetex creates premium motorized screens that provide hurricane-rated weather protection for residential and commercial spaces, backed by a lifetime warranty.

COMPANY

RETRACTABLE SOLUTIONS

RESOURCES

© 2025 Go-Fenetex Powered by Friends of Oatis

Go-Fenetex creates premium motorized screens that provide hurricane-rated weather protection for residential and commercial spaces, backed by a lifetime warranty.

COMPANY

SOLUTIONS

RESOURCES

© 2025 Go-Fenetex Powered by Friends of Oatis